Infrastructure Department

After the registration procedure is completed, our plaster models, which represent the standard system, are going to be produced.

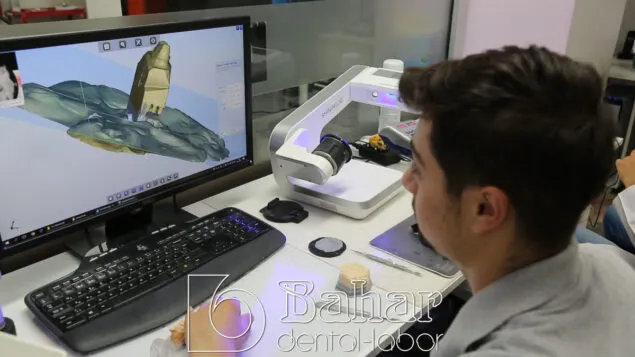

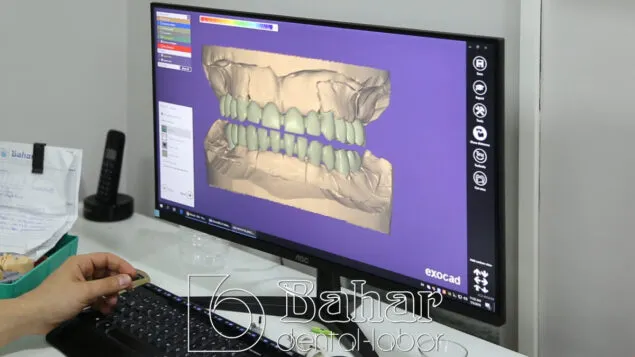

In the infrastructure department, models are also obtained in a digital environment, and models can be obtained with 3D dental design programs on STL data, which were obtained with intraoral scanners. Digital models are produced with 3D printers. In the digital department metal substructures and zirconium infrastructures are designed and processed.

Once the metal infrastructures have been designed in STL format in a digital environment, they are transformed into an infrastructure using chrome-cobalt powders in 3D metal laser sintering machines. All infrastructures are produced with fully-fledged professional machines, which are 2019 models, that work without any errors.

The zirconium dioxide infrastructures, which are prepared in a digital environment, are processed on CNC machines. At the same time, this machine produces infrastructures such as custom abutment, custom telescope and bars, custom hybrid prostheses, custom toronto bridge.